Page 1 of 2

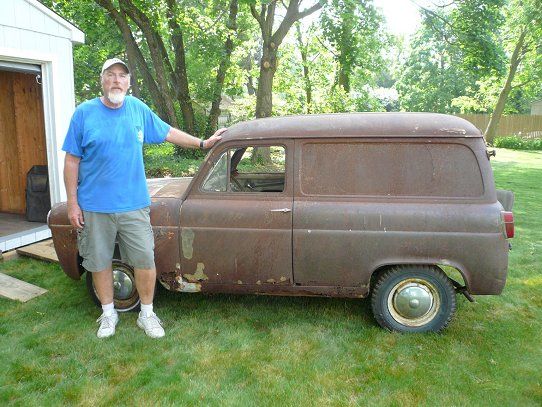

1959 Thames 300E

Posted: Sun Aug 25, 2013 4:40 pm

by BigFred

I was documenting my slow-moving project on a UK-based forum and someone recommended that I check in here. I'm based in New Jersey, USA.

A few months ago I acquired a '59 Thames 300E (actually 301E I guess) from my brother for free. The body is in poor condition, but we believe the engine can be gotten to run with enough work (and hopefully not too much $). My plan is to see if I can actually get motor started and then go from there, fixing up the mechanicals and later proceeding to the massive body work.

The motor turns freely, but I found in checking things out that the flywheel bolts were sheered off. Further checking found that a previous owner (prior to my brother) had apparently done some disassembling and lost more than a couple of the bolts from the drivetrain. The flywheel had been reattached with an assortment of lightweight bolts and a brass screw. The flywheel alignment dowel/pin was substituted with a piece of threaded rod in too narrow of a diameter. I guess the task ahead of me will be a challenging one. At least I'm not in a hurry. Wish me luck.

Posted: Mon Aug 26, 2013 9:35 am

by oabandit48

Welcome Fred - get bolts yet ??

Check this link - possible parts ??

http://www.enfostuff.com/forum/viewtopi ... highlight=

Posted: Mon Aug 26, 2013 12:45 pm

by BigFred

Have not received the package yet. I did confirm that the dowel/pin my brother found appears to be the correct one for the Thames flywheel.

Thanks for the lead on a possible source for other parts. Not sure what parts it has that I would need. I may need a solid donor body someday.

Posted: Tue Sep 03, 2013 11:49 am

by BigFred

Package received in today's mail. Very much appreciated.

welcome

Posted: Sun Nov 03, 2013 10:19 pm

by reggie

nice looking english ford there.. here is a picture of my friends ford.

Posted: Mon Jul 28, 2014 7:56 pm

by BigFred

I'm happy to report that I've gotten my Thames engine to fire up for the first time since the 1970's.

Only had it running for a short time (by choice), but that was enough to convince me that it WILL run and the project may be a viable one. Now onto disassembling and repairing the various systems on it. The extensive body repairs will come last. Wish me luck.

Posted: Mon Jul 28, 2014 8:58 pm

by Brett Wilkie

I think you are doing well, at least you are making steady progress. My 100e cars will sometimes sit for months without any attention at all.

301 e

Posted: Mon Jul 28, 2014 10:18 pm

by DonG

You have a unique vehicle. People are amazed at classic car shows about the existence of Anglia's. Your van is raaaare. Although it is a working mans vehicle, it is still valuable due to its uniqueness. Make it a working van will have added value.

Posted: Wed Jul 24, 2019 6:58 pm

by BigFred

This is a combination project update, confession and parts inquiry. A few years ago, as part of my project, I asked this Enfo community about the availability of some small parts I needed to correctly mount the flywheel on my Thames 300E. A previous owner had mounted the flywheel with an assortment of screws and odd bolts and they all broke off in the crankshaft. (I think I have a thread somewhere on this forum about that issue.)

A couple of very generous guys in this community sent me the bolts, alignment pin and flange I needed. I extracted the broken-off screws/bolts and proceeded to mount the flywheel using the correct parts. As I was torqueing down the flywheel bolts I noticed that one of them wouldn't tighten. I also couldn't remove it, no matter what I tried. That episode was so disheartening & frustrating I completely stopped working on the project for a couple of years.

I was recently convinced by my brother to take one more shot at removing the bolt, identifying the problem and fixing things. If I couldn't get beyond this issue, I was going to sell the car. After some dedicated work today, we got the bolt removed, saw that some of the threads were stripped off, used a tap to clean up the threads in the crankshaft, and put the remaining three flywheel bolts back in.

Now I'm on the lookout for one flywheel bolt to replace the one I somehow ruined.

Posted: Thu Jul 25, 2019 7:11 am

by enfoprefect

What is "special" about that bolt Fred? It has been a while for sure but I seem to recall it was just a hardware store bolt.

Posted: Thu Jul 25, 2019 9:22 am

by BigFred

enfoprefect wrote:What is "special" about that bolt Fred? It has been a while for sure but I seem to recall it was just a hardware store bolt.

I don't have a good answer for that question. I just know that when I posted an inquiry about these bolts previously, I was provided a specific set of them. They have no threads on the quarter inch closest to the head. I was using a 13mm socket to tighten them (but it looked a 1/2" socket might work too). They're marked "Wiley V" on the head.

Posted: Fri Jul 26, 2019 6:12 am

by enfoprefect

Hmmm, interesting.

Posted: Fri Jul 26, 2019 7:35 am

by JAN

From memory, they're 5/16" UNF - interchangeable with S.A.E. - and have 1/2 inch AF (across flats) heads. Half an inch is 12.7mm, so using 13mm tools can round off the corners. I imagine they're high tensile steel but not certain on that.

Posted: Fri Jul 26, 2019 2:35 pm

by mark

they are similar in shape to the flathead v8...which the head was taller than a stock bolt. I ran a chevy disc in a flathead v8 which barely hit the bolt head, so I replaced them with ARP flywheel bolts ...which had shorter head height. Someone on the site must have another bolt for you, but if not, ARP will have the flywheel bolts. I agree with Jan's comment they are SAE and probably high tensile.

Posted: Thu Aug 01, 2019 12:15 pm

by BigFred

Couldn't find the correct size on the ARP site. I picked up a bolt from the local NAPA auto parts store. It's the correct thread size (5/16-24), socket size (1/2"), and length (just shy of 1") in Grade 8. Unfortunately it's threaded all the way up the shank, unlike the original. I'm not sure what effect that might have. I'm going to keep looking for an original.