Need engine info

Need engine info

Ok i finaly got a title on my Squire. and am ready to get her running. the compression is low and I want to replace the rings. I look on the common sites but I need to now what engine I have so I can order some. I have a numbers matching 57 Squire. I pulled the head and it looks to be standard pistons .I cant find any info on this car . any help is apprecated[/img]

Live your dreams

I can't quite figure out what the information is that you need. All Squires used the 1172cc sidevalve 100E engine common to all models., For a given oversize, pistons and rings are common throughout the range.

There are some peculiarities with overhauling this engine that you need to be aware of though. Firstly, they have a low compression to start with: 125psi on a new engine, but will run happily with only 75psi, or sometimes lower. The important point is that the lowest compression pressure be at or above 90% of the highest.

These engines break rather than wear rings. The top one breaks first, and although the engine now has a slight rattle, it will run without problems with all top rings broken. Eventually a second ring will break on one piston. All compression on that cylinder will then be lost to the sump, where it will pump the oil out of every known orifice and breather at an alarming rate. Until that stage arrives, you're better to leave well alone.

Once you do dismantle, you might be in a for something of a surprise. Firstly, you need to measure the vertical clearance of the rings in their grooves. If these exceed 0.004" to 0.0045", the new rings will rattle up and down within the enlarged grooves as the piston changes direction at TDC and BDC. This hammering action will shatter the new rings at about 6,000 miles.

You’ll also find that the connecting rod big ends are direct metalled: the white metal is poured into the rod then machined to size. You will find that, even if not worn oversize, the metal will have holes in it where some has broken away. Needless to say, remetalling is a skilled and expensive business. There was conversion to rods available to allow them to accept shell bearings, but this costs as much as the remetalling process, and in my experience isn't always successful.

Sorry to be the bearer of bad news but, unless really necessary, leave the engine alone.

There are some peculiarities with overhauling this engine that you need to be aware of though. Firstly, they have a low compression to start with: 125psi on a new engine, but will run happily with only 75psi, or sometimes lower. The important point is that the lowest compression pressure be at or above 90% of the highest.

These engines break rather than wear rings. The top one breaks first, and although the engine now has a slight rattle, it will run without problems with all top rings broken. Eventually a second ring will break on one piston. All compression on that cylinder will then be lost to the sump, where it will pump the oil out of every known orifice and breather at an alarming rate. Until that stage arrives, you're better to leave well alone.

Once you do dismantle, you might be in a for something of a surprise. Firstly, you need to measure the vertical clearance of the rings in their grooves. If these exceed 0.004" to 0.0045", the new rings will rattle up and down within the enlarged grooves as the piston changes direction at TDC and BDC. This hammering action will shatter the new rings at about 6,000 miles.

You’ll also find that the connecting rod big ends are direct metalled: the white metal is poured into the rod then machined to size. You will find that, even if not worn oversize, the metal will have holes in it where some has broken away. Needless to say, remetalling is a skilled and expensive business. There was conversion to rods available to allow them to accept shell bearings, but this costs as much as the remetalling process, and in my experience isn't always successful.

Sorry to be the bearer of bad news but, unless really necessary, leave the engine alone.

I had 100 on # 1 ,60 on 2and 3 and 90 on 4. the engine would not run it would act like it wanted to but wouldnt . a little oil would bring 1 to 125 , 2&3 to 90 and 4 to 100 but still no run. I just want to change the rings. the rest looks fine. as far as the information I was asking for you gave me. i didnt know the cc's

Live your dreams

-

enfoprefect

- Posts: 185

- Joined: Wed Feb 04, 2009 10:24 pm

- Location: Oklahoma City

- Contact:

Ok well You think I could reuse the copper gasket for the head. because I can put it back together set timming again and go from there. by the way is there any service manuals or books for proper specks on torque settings for the head, and setting timming. I've been just bringing 1 up on the compression stroke using a bent screw driver to make sure the piston is all the way up and checking the rotor to make sure its on the right plug. it looks like there is a bump on the timming cover at around the 2-3 oclock position that lines up with the notch on the lower pullywhen number one is up. Im assuming that this is the TDC mark?

Live your dreams

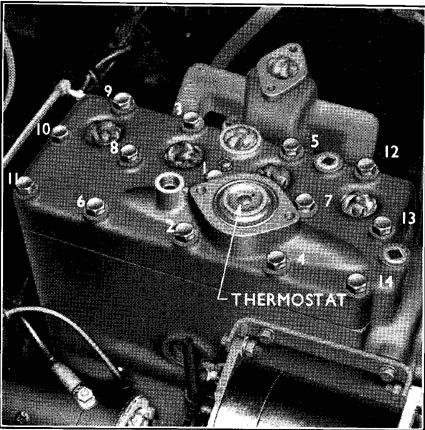

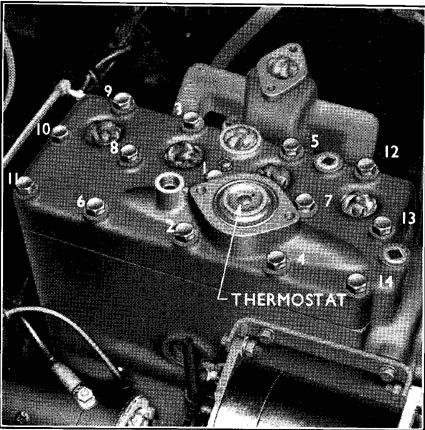

Head Torque setting is 65-70lb.ft. Torque sequence is:

I've reused the copper gasket successfully in the past, but no guarantees!

The notch in the front pulley and on the cover line up 5 degrees BTDC - the correct static timing. If you look down the plug holes as you rotate the engine, you can see the valves opening and closing. As the pulley mark approaches the timing cover mark, the exhaust valve on no 4 cylinder should be closing. You are then set for the rotor to point at No 1 in the distributor cap.

I've reused the copper gasket successfully in the past, but no guarantees!

The notch in the front pulley and on the cover line up 5 degrees BTDC - the correct static timing. If you look down the plug holes as you rotate the engine, you can see the valves opening and closing. As the pulley mark approaches the timing cover mark, the exhaust valve on no 4 cylinder should be closing. You are then set for the rotor to point at No 1 in the distributor cap.