----------------------------------------------------------------

CLEAN CYLINDERS UP BEST YOU CAN AND PUT IN OVEN @ 450 DEGREES 20 - 30 MINUTES THEN APPLY 140 POUNDS AIR PRESS , KEEP THE BLEED SCREW CLOSED. REHEAT IF IT DONT WORK THE FIRST TIME AND BE CAREFULL IF YOU MAYBE BY CHANCE HAVE HAD SOME BEERS BECAUSE YOU COULD BURN YOURSELF !!!! OUCH ! HOT HOT !

USE A DREMEL TOOL TO CLEAN THE CORROSION WRITE WHERE THE PISTON GOES INTO THE SLEAVE

THIS IS THE BEST WAY I FOUND TO BE ABLE TO GET THE PISTON OUT OF CYLINDERS THAT HAVE BEEN FROZE FOR 40 PLUS YEARS .

P J RATZLAFF === FAT DADDY ===

HAM LAKE , MINNESOTA 55304

----------------------------------------------------------------

I have a grease gun dedicated just for seized brake pistons. The gun nozzle is screwed directly into the connection for the brake line on the cylinder, and with the bleeder valve closed, pump grease into the cylinder. It almost always frees up and pushes out the stuck piston.

Then clean out the grease and hone the cylinder.

Toni

----------------------------------------------------------------

I'm sure significant others would prefer the grease gun method over the oven...unless of course it's their grease gun.

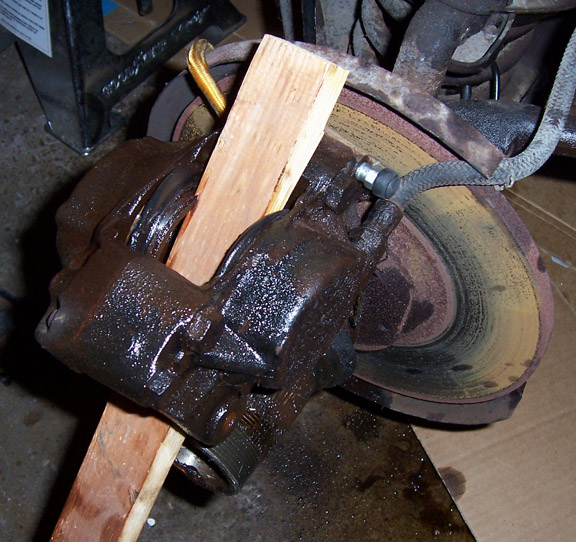

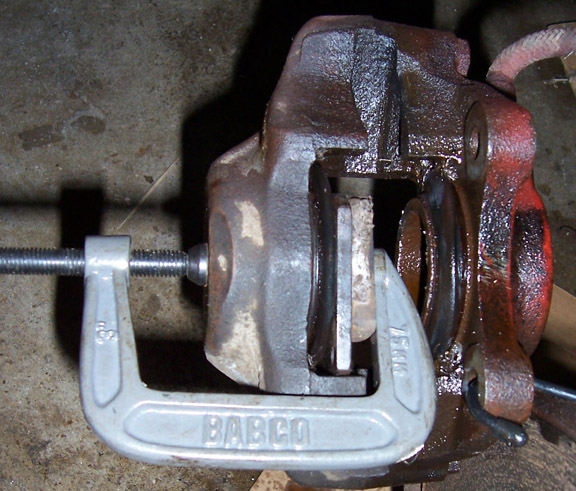

I had a frozen set of dual piston calipers, on a 64' Sunbeam Alpine. I unbolted the caliper, stuck a piece of wood where the disc would go (to make sure the piston would not come all the way out) then pumped the brake till one broke loose. I then used a C-clamp to hold the loose piston, and pumped till the other broke loose. Of course I soaked the heck out of them with penetrating oil for a couple days in advance.

-------------------------------------------------------------