Hi all,

Finally got the motor fired up for the first time since I bought it almost a year and a half ago.

It runs, idles fine now I have questions.

I have a spare dizzy I got with the car which has a advance curve on it according to the guy who sold me the motor.

Its a Bosch Electric Unit, allegedly "recurved" for a 286 Cam I was told. My other distributor was being a pile of crap so in came this one.

Bosch JGFUX4 86BF12100BA 0237601008

Motor is a 681F out of a Cortina GT. Swapped Carb for Twin Weber 40s. Running electric fuel pump with FPR set at about 2.5LBS

Motor will fire up and idle fine, I have it set at 12°

Think my carbs are running rich at the moment but that's another thing.

Talking with another fellow he mentioned I need a timing gun where you can set the timing on it..

As I had my gun on the timing marks and revved up the motor to over 2500 rpm I didn't see the mark advance at all.

Questions are as follows..

-It is perhaps advancing and I'm not seeing it with my old fashioned gun? (No backfires, no hesitation when I blip the throttle) It's running an open header right now so I do hear a pop from the rich mixture I have at the moment.

-What is the ideal amount of advance for my setup? How can I find the advance of my distributor and the best way to match the timing of my motor to that.

-Is there any danger to running the motor with an advance curve that is not specifically dialed in for my camshaft. Should I be pulling the distributor apart and adjusting the weights inside?

If my questions seem quite novice I apologise just looking to learn and for any help anyone can provide.

Thank you very much!

Setting Timing

-

Brett Wilkie

- Posts: 1832

- Joined: Sun Sep 16, 2012 12:42 pm

- Location: Vancouver British Columbia Canada

I think whatever you do make sure it doesn't over advance (34 degrees max) or you can wreck your new engine. I think Bosch distributors are good quality so you should use it, I assume it is a non vacuum advance type? I tossed the crappy stock FoMoCo distributor in favour of the Lucas units that I have a number of and trust, I was also lucky to have a distributor machine to re-curve them as I pleased. I ended up giving that machine away to my friends shop when I sold my Vancouver house, it is great tool to have around but too much stuff to move to the Sunshine Coast.

Are you using the stock crossflow crank pulley? If yes you might want to consider this one I used, it is solid and smaller diameter and I found that is good too for putting your own timing marks on. It won't blow up at high revs and it serves as an under drive pulley so as not to over speed your water pump and generator/alternator. It is the same spec as the stock Twin Cam engine.

http://www.burtonpower.com/v-pulley-cra ... fp224.html

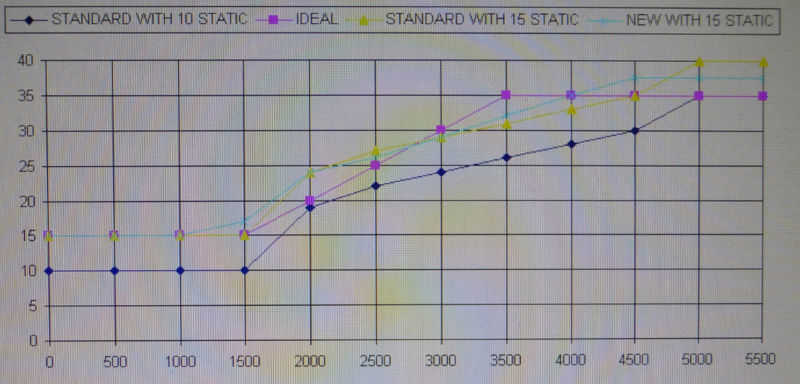

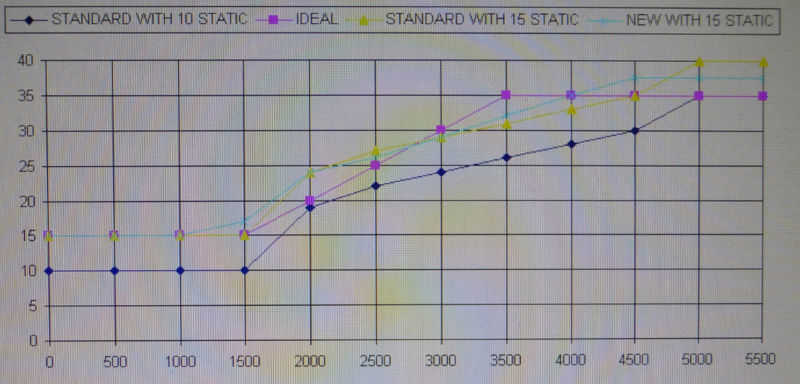

You can use a protractor to measure out and mark the pulley, I would mark it at about 34 degrees which is about as far as you want to go with safety on that engine and that should be met at around 3500 crank RPM. I have not yet driven my own car so I can't say about performance yet. I am using a non vacuum distributor with a centrifugal advance of about 10 degrees (20 crank degrees), my static timing set at 12 to 14 degrees so total comes out to 32 to 34 degrees. Here is a picture of what I tried to get the advance curve to follow the ideal.

Just mark your pulley at 34 degrees away from TDC, that mark should be near TDC at about 3500 RPM if all works out.

I still have some fooling around to do as too high a static timing combined with high compression can cause slow cranking speed and hard starting, 15 degrees seems high to me but we will see as it comes??

Are you using the stock crossflow crank pulley? If yes you might want to consider this one I used, it is solid and smaller diameter and I found that is good too for putting your own timing marks on. It won't blow up at high revs and it serves as an under drive pulley so as not to over speed your water pump and generator/alternator. It is the same spec as the stock Twin Cam engine.

http://www.burtonpower.com/v-pulley-cra ... fp224.html

You can use a protractor to measure out and mark the pulley, I would mark it at about 34 degrees which is about as far as you want to go with safety on that engine and that should be met at around 3500 crank RPM. I have not yet driven my own car so I can't say about performance yet. I am using a non vacuum distributor with a centrifugal advance of about 10 degrees (20 crank degrees), my static timing set at 12 to 14 degrees so total comes out to 32 to 34 degrees. Here is a picture of what I tried to get the advance curve to follow the ideal.

Just mark your pulley at 34 degrees away from TDC, that mark should be near TDC at about 3500 RPM if all works out.

I still have some fooling around to do as too high a static timing combined with high compression can cause slow cranking speed and hard starting, 15 degrees seems high to me but we will see as it comes??

Anglia 100e modified

Prefect 100e stock

Prefect 100e stock

It's a non vacuum centrifugal advance. Like I said it's got the weights in there, can't tell you how much advance the thing puts out. Been learning about ignition and distributors for the past few days now getting the hang of it. A lot of the stuff I'm doing is learn as I go.

Fancy machine!

I may have dialed it up to 35 for a few seconds but appears unharmed.

If I had it set to 12 and revved it it would sputter trying to go above 1500-2000 rpm when you tried to rev it. 34 was smooth all the way through the rev range so not sure if it's just locked out from sitting too long or maybe it advances super early? Although it did idle super high with the advance timing..

Not sure how well my carbs are set up but i could open it right up to 6k with no hesitation. need to start building that exhaust

need to start building that exhaust

Will let it sit for a few days and fire it up again Friday and see what happens.

Fancy machine!

I may have dialed it up to 35 for a few seconds but appears unharmed.

If I had it set to 12 and revved it it would sputter trying to go above 1500-2000 rpm when you tried to rev it. 34 was smooth all the way through the rev range so not sure if it's just locked out from sitting too long or maybe it advances super early? Although it did idle super high with the advance timing..

Not sure how well my carbs are set up but i could open it right up to 6k with no hesitation.

Will let it sit for a few days and fire it up again Friday and see what happens.

-

Brett Wilkie

- Posts: 1832

- Joined: Sun Sep 16, 2012 12:42 pm

- Location: Vancouver British Columbia Canada

Make sure that the centrifugal weights are lubed and moving, you might want to find a shop with a distributor machine just to know what it tops out at in advance. I guess, like myself that you will have to experiment with your timing and fuel. The short running over advanced may not hurt it, you just don't want to keep driving it like that, I have heard of guys melting their pistons. It looks like a lot of different engine types enjoy similar timing specs.

The pulley is not so critical, when I look through the Ford units I have I noticed only some were the dangerous pressed steel, held together with rivets type. The others seem to be a safer cast type.

The pulley is not so critical, when I look through the Ford units I have I noticed only some were the dangerous pressed steel, held together with rivets type. The others seem to be a safer cast type.

Anglia 100e modified

Prefect 100e stock

Prefect 100e stock